Polyester Tandem Centrifugal tanker

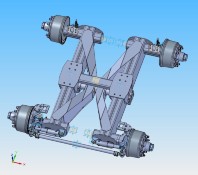

For more than 20 years the BAUER tandem-pendulum axle has been a fixed part of the equipment of our tankers. The special distribution of load between the axles in the front and in the back and the axle bars which oscillate independently of each other care for a good driving behavior. A uniform ground contact pressure on all four wheels can only be reached by this pendulum aggregate. The centrifugal pump achieves high and constant outlet pressure, the filling is done via external pumps.

Standardlieferumfang:

- Container made of polyester laminate with gel coating

- Baffle plate

- Profile frame galvanized, running through as a fixed drawbar

- Wheel cut running through for the possibility to adjust the axle

- Filling dome hydraulic square with sliding lid

- Single axle

- Air brake system, dual circuit system

- ALB - automatic load dependent brake regulation

- Filling level indicator in the front

- Supporting leg and wedges

- Lighting device 25 km/h

- Original BAUER centrifugal pump, drive speed 540 min-1

- Mixing device via bypass flushing device

- Pressure line installed underneath the container D133mm

- Discharge valve (3-way gate valve) hydraulically double acting HK 133 socket

- Quantity dosage device at the 3-way gate valve manually operated

- Distributor head with cast blockage nose; HK 133 - ball with lever closing ring

- PTO shaft wide angle unilateral with shear bolt, profile 1 3/8"-1 3/8" 6-parts, for centrifugal pump

- Overflow / aeration and ventilation

- Operating and maintanance manual