RAINSTAR E

Success with a high level of quality

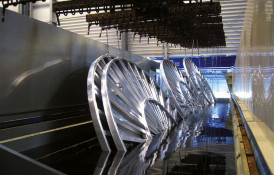

Reliability, durability and efficiency are the main requirements of an irrigation machine. With the RAINSTAR E models the requirements are not only met but exceeded. This generation of RAINSTARs presents itself in a completely new design. The hot dip galvanized steel construction is visible proof of the traditional BAUER synthesis of technology, robustness, durability and design. The entire production is made according to the highest quality standards according to the self-imposed ISO 9001 standards.